Brine Management

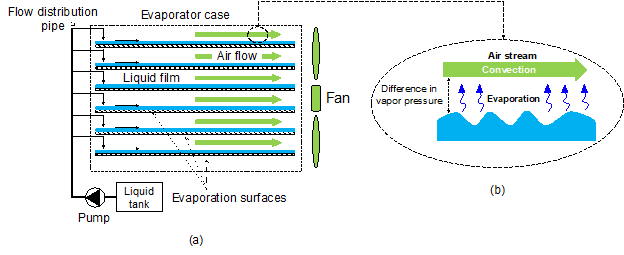

The team is working on the development of a novel convection-enhanced evaporation (CEE) system. The proposed system represents a modular brine management option for decentralized desalination plants and small-scale industries. Brine is released over horizontally packed evaporation surfaces forming liquid films and forced convection is induced by means of a fan. As air flows over liquid films, the difference in vapor pressure between the air and liquid surfaces induces evaporation. The project includes mathematical modeling, design optimization and experimental testing.

In-Situ Synthesis of Peritoneal Dialysate

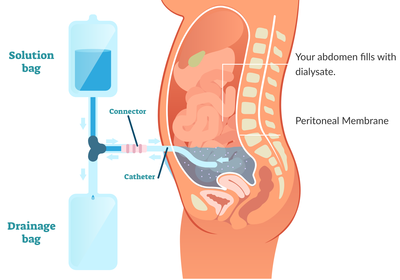

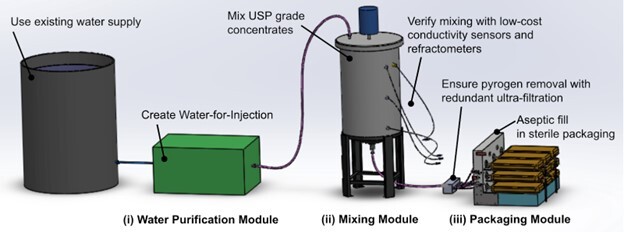

Limited access to dialysis, the life-saving therapy for end-stage kidney disease (ESKD) and acute kidney injury (AKI), may result in up to 7 million deaths every year, more than from HIV and Tuberculosis combined. Peritoneal dialysis, a treatment option that can be performed by patients in their homes, has the potential to improve access, but lack of local production and importation challenges in many low- and middle-income countries make it unaffordable. Our goal is to produce peritoneal dialysis fluid locally to reach patients at a scale that is impossible with the facility and labor constraints of in-center dialysis. We are developing a system that generates water for injection and is able to mix and package the final solution without an expensive cleanroom facility. This project aims to decentralize manufacturing to allow rapid, on demand production in disaster situations, during shortages, in military/war zones, or in countries where importation problems result in unaffordable costs.

Gas Extraction in Anaerobic Wastewater Treatment

Anaerobic wastewater treatment is used across the country to treat both household and industry wastewater and consumes ~25 million kWh of energy in the Twin Cities alone, costing approximately $1.7 million/year. This cross-departmental project aims to build an anaerobic wastewater treatment system that recovers the energy consumed in the form of hydrogen and methane gases collected from the liquid effluent of the wastewater treatment system. This project aims to investigate and determine the most efficient gas extraction system through both modelling and experimental work.

This work is a joint effort with Prof. Paige Novak (Civil, Environmental, and Geo- Engineering, UMN), Prof. Bill Arnold (Civil, Environmental, and Geo- Engineering, UMN), and Prof. Jeremy Guest (Civil and Environmental Engineering, University of Illinois at Urbana-Champaign).

Food Loss Reduction through Evaporative Cooling and Dehydration

With an estimated one third of food produced for human consumption being lost or wasted globally, Sustainable Development Goal 12.3 calls to halve global food loss and waste by 2030. If crops are not promptly cooled to optimal temperatures or properly managed after harvest, the quality, shelf-life and marketability rapidly decrease. This project seeks to investigate the circularity of the food-water-energy nexus to reduce postharvest food loss in resource constrained settings, with particular focus on evaporative cooling and dehydration technologies and processes for applications within the Kenyan context.

Electrodialysis (ED) Desalination

Electrodialysis (ED) is one of the leading technologies for application such as groundwater desalination. Groundwater accounts for nearly one-third of Earth’s freshwater resources; however, salinity levels are often too high for continuous human consumption. Electrodialysis uses electrical current and ion-selective membranes to separate salt components in feedwater, thus creating streams of high and low salinity. Feedwater temperature and conductivity may have a significant impact on the system’s desalination rate, limiting current density, and total energy consumption. These impacts were modeled and will be tested on bench-scale setups.